What you Need to Know About Reciprocating Gas Compressors

A 6 Part Blog Series

by Randy Franiel, Compass Senior Accounts Manager, Canada

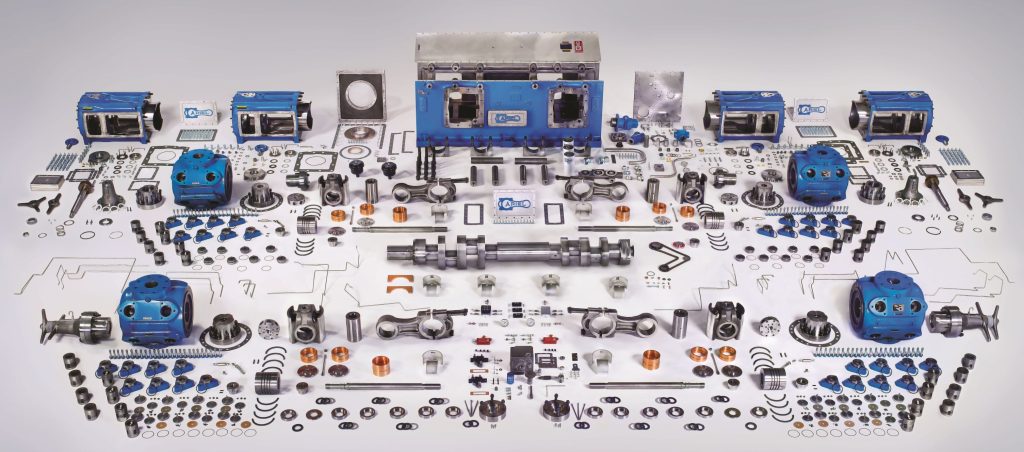

What do you see when you look at this picture? Most people see complexity. They see hundreds of parts and components of different shapes and sizes that together make up a modern reciprocating natural gas compressor.

My name is, Randy Franiel, and as a Senior Accounts Manager with Compass, I see it a little differently. I live and breathe this stuff. Over the past 29 years, in fact, I’ve taught many courses for Compass employees, clients, and others, on how gas compression works and how to maximize a unit’s efficiency and a producer’s profitability. Those courses range in length from a few hours to several days.

When I look at this picture, I don’t just see 209 distinct parts. I see 6 critical areas where many compressors, and many producers, can achieve higher production for the money spent, and a bigger profit at the end of the day.

Join me over the coming weeks as I explore these 6 critical areas, as well as how to use this knowledge to move more gas, make more money and have a safer unit doing so.

If you have questions about reciprocating compressors or gas compression,

please contact Randy Franiel by email or phone: 1-855-262-2487

Email Us

What you Need to Know About Reciprocating Gas Compressors

Have you read all the articles in our blog series?

Intro: What You Need to Know about Reciprocating Gas Compressors

Part 1: How a Fundamental Design Flaw Robs Your Profits

Part 2: Understanding the Importance of Shaking Forces

Part 3: Volumetric Efficiency: Why it Matters and How to Maximize It

Part 4: An Approach to Compressor Selection, and the #1 Issue to Watch For

Part 5: Your New Gas Compressor is Installed. Do THIS Before it Goes Online

Part 6: When Gas Compressors Operate Outside Design, Communication is Key