Understanding the Importance of Shaking Forces

by Randy Franiel, Compass Senior Accounts Manager, Canada

I’ve worked in this industry for 29 years and I’ve seen the stress and damage caused by shaking forces within a recip compressor package. To me, the impact and cost of shaking forces isn’t understood nearly well enough, and for this reason, the impact of shaking forces isn’t a prime consideration during the design process. It should be.

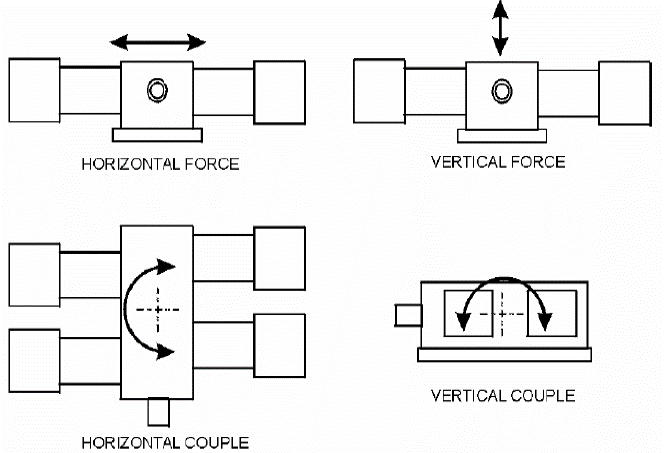

The inherent design of a reciprocating compressor results in shaking forces. These forces occur on each cycle. As the piston travels outward, a Horizontal Primary Force to the crankshaft happens. Looking at this closer, consider the compressor cycle or rotation. As the piston, crosshead, conrods, etc. travel back and forth, a force is required to accelerate the overall mass from zero velocity at the end of each stroke to high velocity at mid-stroke, and back again to zero. This happens over and over again.

This Horizontal Primary Force can be offset by the use of counterweights that oppose the outward direction of the piston, crosshead, etc.

The Horizontal Secondary Force is much smaller than the Primary Force, and is due to the connecting rod motion around the crankshaft centerline. This Secondary Force, like the Primary, also happens twice per revolution.

By using counterweights to offset the Horizontal Primary Forces, the introduction of a Vertical Primary Couple happens, adding still more shaking forces. At midpoint of the piston throw-through rotation, the counterweight is perpendicular to the piston motion. This mass translates into a vertical force, pulling the compressor frame upward, or downward depending on the position of rotation.

The inherent design of a compressor’s shaking forces acts on all three axes. Knowing that this happens and cannot be prevented, can it be minimized? The answer is: Yes. It can be minimized by understanding what the primary cause for the force is, and then minimizing and/or managing that cause.

Yes, Ariel frames are designed to run at rated speed and subsequent vibration caused by these forces. Our skid designs are specifically suited to handle these forces, full depth skid gussets, oversized main skid members, etc. are all there to manage these vibrations levels. However, if your application permits, and a short-stroke frame can be used, you can see efficiency gains while minimizing these forces and reducing vibration load.

Let’s look at two compressors in a given application: a long-stroke Ariel JGC/4 (6.50”) and a short-stroke JGD/4 (5.50”). The JGC was designed to run at 1,000 rpm, while the JGD runs at 1,200 rpm. If we look at the piston speed in feet per minute (stroke length x rpm x double acting design ÷ 12”/ft) the piston speed of the two is very comparable. The JGC is at 1,082 fpm, with the JGD at 1,100 fpm. However if we run the JGD at 1,000 rpm, being the shorter stroke, we get 916 fpm. This is an 18% reduction in piston speed and ultimately a reduction in Horizontal Primary Force.

These lower forces translate into less shaking. It also means the forces acting on your site foundation will be lower. These lower forces may result in less-costly foundation designs which are required to constrain these forces. With lower levels of vibration, lower maintenance costs are expected as well.

So with the benefit of a shorter-stroke compressor, why do we need a long-stroke frame? The answer is: rod load. If the rod load is getting too high, this can be lowered by using a longer- stroke compressor and having a smaller bore. This would preclude the use of a short-stroke design. This is an example of why shaking forces must be fully considered in the design process.

One other item to consider in the reduction of vibration levels is the Dynamic Restraint of a Compressor Discharge Bottle. The packaging sub-systems addition of a restraint or support to the pulsation bottle can control the vibrations by changing the resonant frequency by adding stiffness, and/or damping. Bottle wedge supports and tie downs can be easily added to the underside of a pulsation bottle. However, when temperatures of the gas are high, the tie down must be carefully designed.

These supports on the discharge bottle are very effective in controlling vibration of many compressor manifold modes. Generally, it is recommended that the discharge bottle be supported by a wedge support, located under each cylinder with the ends of the bottles with a bottle wedge/strap combination support. (I discuss this further in an upcoming blog, so stay tuned).

In a nutshell, here’s what I’ve learned over 29 years in this game: always select a shorter-stroke compressor over a longer-stroke compressor when not a requirement of rod-load limits. Run it slower rather than faster. Choose bigger cylinders and the bigger valves that go with them. This way, the compressor can breathe. You’ll be operating well within the machine’s limits, not pushing the limits out there on the edge. Your equipment will last longer, and your downtime and maintenance costs will be lower.

If you have questions about reciprocating compressors or gas compression,

please contact Randy Franiel by email or phone: 1-855-262-2487

Email Us

What you Need to Know About Reciprocating Gas Compressors

Have you read all the articles in our blog series?

Intro: What You Need to Know about Reciprocating Gas Compressors

Part 1: How a Fundamental Design Flaw Robs Your Profits

Part 2: Understanding the Importance of Shaking Forces

Part 3: Volumetric Efficiency: Why it Matters and How to Maximize It

Part 4: An Approach to Compressor Selection, and the #1 Issue to Watch For

Part 5: Your New Gas Compressor is Installed. Do THIS Before it Goes Online

Part 6: When Gas Compressors Operate Outside Design, Communication is Key