Our Frontier facility enables us to provide one-stop shopping for our clients enabling us to deliver compression and process packages to their schedules and budgets.

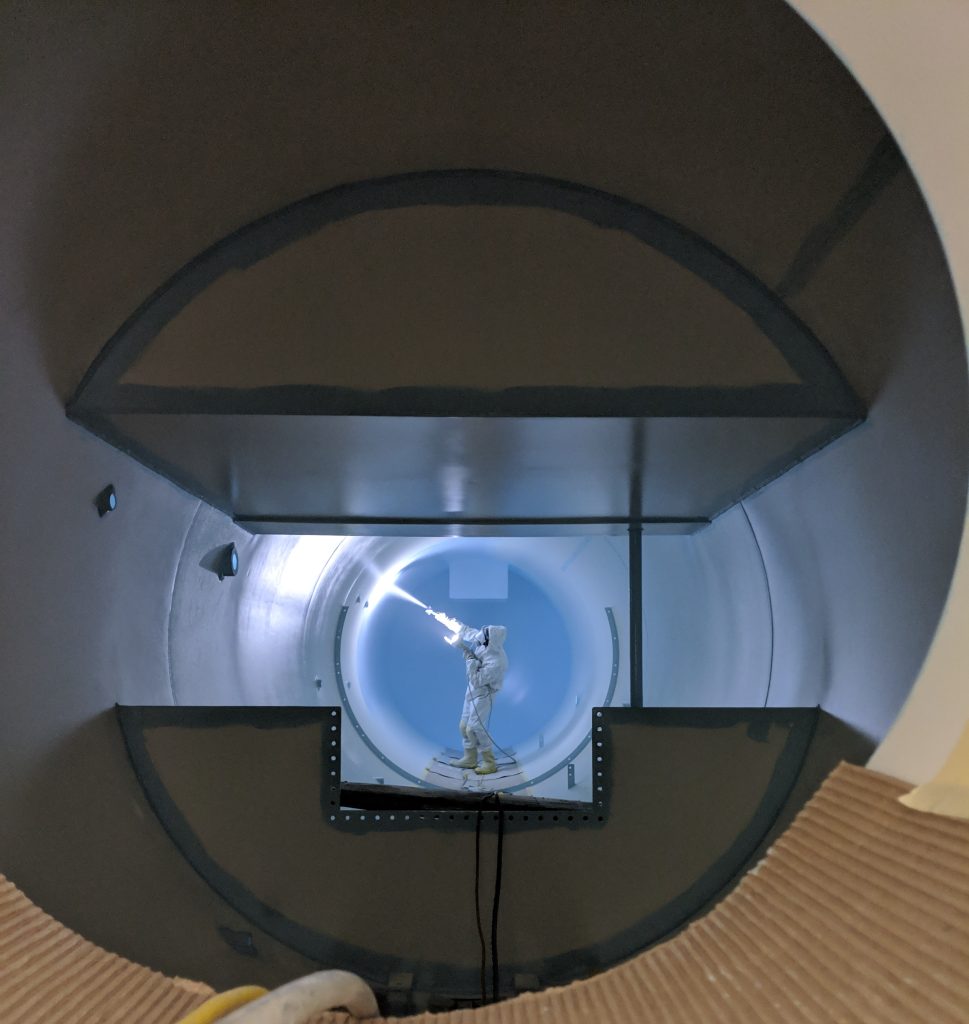

Everything in Frontier has been designed with a purpose. Our compression and process equipment sand blast and paint bays are state-of-the art and benefit our clients in many ways:

- Our sand blast bay has an auger media recovery system that keeps consumable costs down.

- We have full control of the ambient conditions during sand blast and coating application to ensure top quality.

- We use specific internal coating equipment that reduces the possibility of product contamination or mixing.

Certified and Experienced Team

- Our Coating Inspector has NACE Coating Inspector Level 2 / API 510 certification.

- Sand blasters and applicators have experience with applying internal coating, and will be taking NACE applicator course.

- Our Compass procedures have been developed with NACE Coating Inspector Level 3.

Inspection and Testing

- Compass strictly adheres to the Coating Manufacturer’s Application Guide.

- Calibrated testing and measuring equipment.

- Comprehensive and in-depth internal coating reporting including pre-blast, blast, application and final inspection reports.