By Scott Douglas, P.Eng.

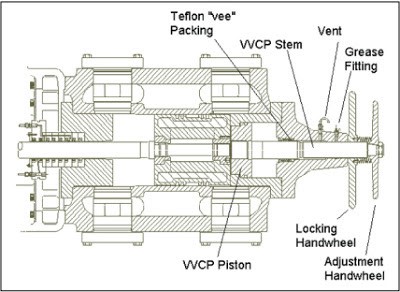

First of all, what is a Variable Volume Clearance Pocket (VVCP)?

A VVCP is a device installed on the outer end (Head End) of a double-acting reciprocating cylinder that can add clearance to a cylinder by turning the pocket out.

Secondly, why do we use VVCPs?

- For capacity control/horsepower (HP) limitation. This is typically for the first stage (stage-1) cylinder(s) of a single or multi-stage reciprocating compressor.

- To reduce rod load or discharge temperature/ratio control on a stage, by shifting the ratio to other stage(s).

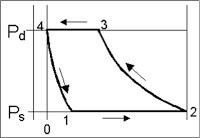

Before examining how VVCPs affect capacity let’s look at an ideal P-V (Pressure-Volume) diagram. Figure 2 below shows the relationship, in one end of a double-acting cylinder, between pressure and volume (piston location).

- From point 1 to 2, the suction valve opens because the cylinder’s internal pressure is less than external suction pressure; this draws gas into the cylinder.

- From point 2 to 3, gas compression begins when the suction valve closes

- From point 3 to 4, compressed gas is discharged from the cylinder; when internal pressure is greater than external discharge pressure, the discharge valve opens.

- From point 4 to 1, the discharge valve closes and suction valve remains closed until it reaches point 1. This is because of the trapped gas in the fixed clearance of the cylinder.

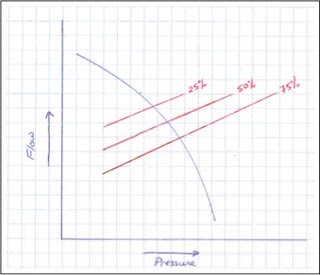

For a gas gathering application, when a stage 1 VVCP is opened, the flowrate of gas (Q) will be reduced and the suction pressure will increase (assuming no pressure restriction / control on wellhead or package). An example of this is shown below with gas compressor capacity curves with 25, 50 and 75% VVCP shown, overlaid on a production curve. ‘

A typical well production curve will produce at a lower rate with more restriction. With effective displacement reduced, the gas compressor does not pull as hard on the well, resulting in higher pressure/lower flow rate.

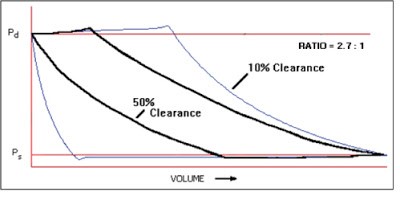

Now let’s look at the effect of opening a VVCP.

By opening the VVCP we add clearance to the end of the cylinder, effectively increasing the re-expansion period, because the larger volume of gas trapped in the cylinder needs to move further during the piston stroke to re-expand out to suction pressure.

On the compression cycle, the piston also needs to travel further along the stroke to reach discharge pressure as there is more volume to pressurize. The ratio of discharge stroke distance with valve open (or suction stroke distance with valve open) over total stroke distance is the discharge (or suction) volumetric efficiency. The smaller volumetric efficiency (VE) of a cylinder, the smaller the effective displacement. Reducing the VE, reduces horsepower consumption (area inside of curve) and capacity moved.

If you have any questions, or would like more information about Compass, please contact the Compass Sales team at 1-855-262-2487.

Download Article (PDF)